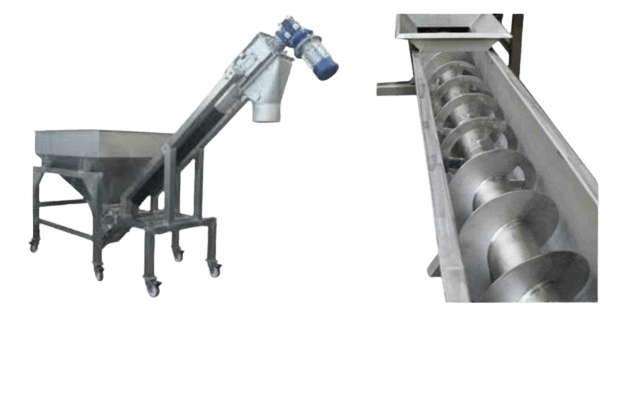

Screw conveyors are among the most widely used material handling systems in industries ranging from food processing and agriculture to chemicals, mining, and wastewater treatment. Their popularity stems from their simplicity, versatility, and ability to move bulk materials in a controlled, enclosed, and cost-effective way.

But while screw conveyors may appear straightforward, designing one that delivers optimal performance requires careful thought. Every material has its own flow characteristics, and every plant has unique operational demands. A poorly designed screw conveyor can result in reduced efficiency, excessive wear, frequent blockages, and costly downtime.

In this blog, we’ll explore the key design considerations for screw conveyors—factors that every engineer, plant manager, or decision-maker should understand before selecting or customizing one for their operation.

1. Material Characteristics

The first and most critical factor in screw conveyor design is the nature of the material being conveyed. Properties such as flowability, abrasiveness, moisture content, and temperature determine the type of screw, trough, and drive system required.

Key material characteristics to consider include:

-

Particle Size and Bulk Density: Fine powders flow differently than large, lumpy materials. Bulk density affects conveyor capacity.

-

Abrasiveness: Highly abrasive materials (like sand, cement, or minerals) require wear-resistant flights and liners.

-

Moisture Content: Sticky or wet materials may cause build-up, requiring specialized screw designs or coatings.

-

Temperature: High-temperature materials call for heat-resistant construction materials and expansion allowances.

By understanding these properties upfront, operators can avoid mismatched designs that compromise efficiency.

2. Capacity and Throughput Requirements

A screw conveyor machine must be designed to handle the required material volume at a given rate. Capacity depends on the screw diameter, pitch, speed, and material bulk density.

Factors affecting capacity include:

-

Screw Diameter: Larger diameters carry more material per revolution.

-

Pitch of the Flight: Standard pitch is equal to the screw diameter, but variable or short pitches can be used for controlled feeding.

-

Screw Speed (RPM): Higher speeds increase throughput but can also lead to material degradation or wear.

-

Loading Efficiency: Usually, screw conveyors operate at 30–45% full to prevent overloading.

Accurate capacity calculations are essential to avoid bottlenecks in production or underutilization of equipment.

3. Conveyor Length and Configuration

The layout of the screw conveyor—its length, angle, and orientation—greatly impacts performance.

-

Horizontal Conveyors: Most efficient and common, ideal for short to medium distances.

-

Inclined Conveyors: Require design adjustments because capacity decreases as the angle increases. Special flights or higher RPMs may be necessary.

-

Vertical Screw Conveyors: Suitable for compact spaces, but need precise design to handle reduced flow efficiency.

Additionally, very long conveyors may require intermediate bearings or multiple drive points to maintain stability and prevent shaft deflection.

4. Material of Construction

Since screw conveyors handle a wide range of materials, the construction material must suit the application’s environment.

Common options include:

-

Carbon Steel: Cost-effective for handling non-corrosive materials.

-

Stainless Steel: Preferred in food, pharmaceutical, and chemical industries for its corrosion resistance and hygiene.

-

Special Alloys: Required for high-temperature or highly abrasive materials.

The right choice balances performance, longevity, and budget while ensuring compliance with industry standards.

5. Trough and Housing Design

The trough (or casing) that encloses the screw is another critical design element.

Types of troughs include:

-

U-Troughs: Standard design, easy to clean and maintain.

-

Tubular Casings: Used for inclined or vertical conveyors where product spillage must be avoided.

-

Special Coatings or Liners: For sticky or abrasive materials, coatings like Teflon or wear-resistant liners are often applied.

The housing should also be designed for easy access to facilitate cleaning, particularly in industries with strict hygiene standards.

6. Drive System and Power Requirements

The drive unit powers the screw conveyor and must be appropriately sized for the load and duty cycle. Undersized drives can cause frequent breakdowns, while oversized systems waste energy.

Design considerations for drives include:

-

Motor Type and Size: Determined by conveyor capacity and operating conditions.

-

Gear Reducers: Match motor speed to the required screw RPM.

-

Direct vs. Indirect Drives: Direct drives are more efficient, while indirect (belt or chain-driven) systems offer flexibility.

-

Safety Features: Overload protection and emergency stops to prevent equipment damage.

Accurate power calculations are essential to ensure reliability and energy efficiency.

7. Flight Design and Modifications

The screw itself is the heart of the conveyor, and its design determines how effectively material moves.

Common flight types include:

-

Standard Flights: For general-purpose conveying.

-

Ribbon Flights: For sticky or viscous materials, preventing build-up.

-

Cut Flights: For mixing and aerating powders.

-

Variable Pitch Flights: For controlled feeding applications.

The right flight design minimizes material degradation, reduces clogging, and improves throughput efficiency.

8. Cleanability and Maintenance Access

For industries like food and pharmaceuticals, easy cleaning is a vital design consideration. Even in heavy industries, accessibility reduces downtime during maintenance.

Best practices include:

-

Quick-release covers for cleaning access.

-

CIP (clean-in-place) systems for sanitary applications.

-

Removable screws for easier inspection and replacement.

-

External bearings and seals to reduce contamination risk.

Neglecting these aspects can lead to product contamination, equipment wear, and higher maintenance costs.

9. Safety and Compliance

Safety is central to screw conveyor design. Moving parts, dust emissions, and potential overloading can pose risks if not addressed.

Key safety features include:

-

Guards and covers to prevent contact with rotating parts.

-

Dust-tight casings for hazardous materials.

-

Pressure relief or explosion-proof designs for combustible dusts.

-

Compliance with OSHA, ATEX, or other relevant safety standards.

A conveyor that prioritizes safety not only protects workers but also minimizes legal and operational risks.

10. Partnering with Experts

Designing a screw conveyor is not just about picking dimensions—it requires deep expertise in engineering, materials science, and application-specific challenges. For this reason, many businesses consult a trusted screw conveyor manufacturer early in the process. Manufacturers can provide tailored recommendations based on decades of experience and testing.

Similarly, working with a reliable screw conveyor supplier ensures access to quality spare parts, timely service, and ongoing technical support. These partnerships often make the difference between a system that struggles and one that performs consistently for years.

Conclusion

Screw conveyors may be simple in concept, but designing one that delivers maximum efficiency requires careful consideration of multiple factors. From understanding material properties and calculating capacity to selecting the right flights, housings, and drive systems, each choice impacts performance, durability, and safety.

By paying attention to these key design considerations and collaborating with expert partners, industries can ensure that their screw conveyors deliver reliable, hygienic, and cost-effective performance for years to come.

Whether you’re moving flour in a bakery, ash in a power plant, or chemicals in a processing facility, the right screw conveyor design is the foundation of a smooth, efficient operation.