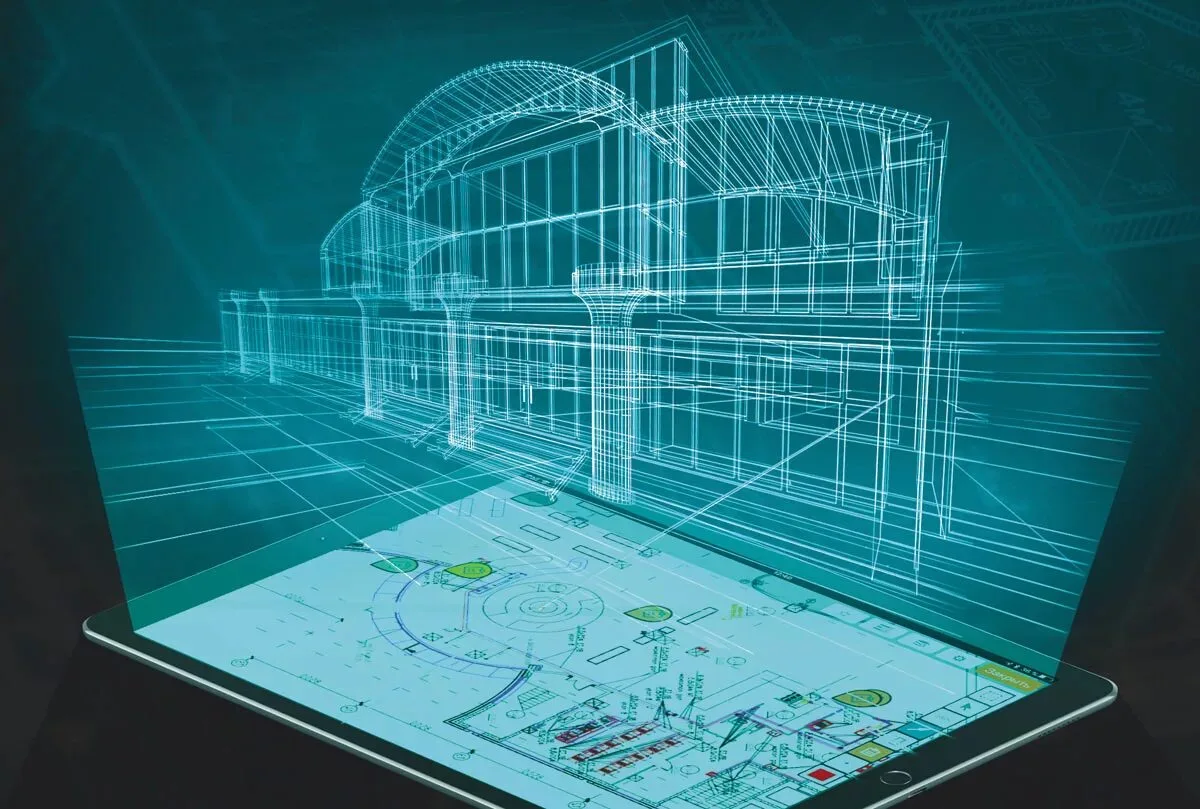

Precision in cost planning isn’t an abstract goal — it’s the practical difference between a project that finishes close to budget and one that becomes a scramble of change orders and disputes. The path to that precision runs through two connected practices: disciplined BIM Modeling Services that produce clean, extractable data, and focused Construction Estimating Services that turn that data into priced, time-phased plans. When both sides agree on simple rules and repeatable handoffs, estimates stop being guesses and start being useful tools.

Why inputs determine outcomes

An estimate is only as good as the numbers it’s built on. If the quantities come from inconsistent drawings, spreadsheets, or hand-measured PDFs, the resulting price will carry those ambiguities forward. By contrast, a model built for measurement holds attributes — material, unit, finish, spatial relationship — that are queryable and auditable. Good BIM Modeling Services supply those attributes reliably; good Construction Estimating Services use them to apply local rates, productivity adjustments, and procurement timing. That chain from model object to priced line reduces assumptions and makes each estimate more defensible.

A short, repeatable workflow

You don’t need a huge digitization program to get precise costs. Adopt a compact loop and repeat it at every milestone:

-

Agree Level of Detail (LOD) and the minimal parameter set up front.

-

Enforce a short naming and tagging guide for families.

-

Run a pilot extract on one representative floor or zone.

-

Condition the export and map families to your cost codes.

-

Apply dated unit rates and lock the procurement baseline.

The pilot extract is the highest-leverage move. It exposes misnamed families and missing tags while fixes are cheap. Fix them early, and the rest of the work flows.

How models reduce common estimating errors

Three predictable problems cause most cost drift: missed repeats, inconsistent units, and undocumented assumptions. Model-driven workflows tackle each one.

First, repeat items behave consistently because families carry the same parameters across floors. Second, units are explicit in the model, preventing conversion errors. Third, when estimators use a dated price library and log sources, each line becomes traceable. When BIM Modeling Services hand over clean exports, Construction Estimating Services convert those exports into priced schedules with fewer iterations and fewer surprises.

Practical checks that protect the estimate

A few quick checks prevent the majority of downstream headaches.

-

Require a one-page tagging guide attached to every model handover.

-

Gate handovers so extractable families have material, unit, and finish.

-

Spot-check a small sample (doors, windows, finishes) before full QTO.

-

Keep a dated price library and record the source for each rate.

These are low-cost controls. They make model output usable and save hours of data cleaning — time better spent testing options and negotiating suppliers.

Mapping model output into commercial terms

A model’s vocabulary rarely matches an estimating team’s cost structure perfectly. The missing step is mapping. Maintain a living table that links model family/type → WBS/cost code → procurement unit. Run a lightweight conditioning pass — usually a spreadsheet or a small script — before importing into pricing software. That intermediate step removes most surprises and keeps Construction Estimating Services flowing without repeated cleanups.

Scenario testing becomes practical

One of the biggest payoffs is speed when testing alternatives. Want to compare two façade systems or try an alternate floor finish? Update the model, re-extract quantities, and reprice. What once took days now often takes hours. Because BIM Modeling Services provide structured quantities, Construction Estimating Services can run multiple scenarios quickly and present owners with evidence-based options rather than a single defensive figure.

The human layer still matters

Models make counting reliable; people give context. No digital file can sense local labor quirks, a narrow site gate, or a supplier’s temporary backlog. That judgment sits with estimators and project managers. The most accurate, buildable budgets come from model-derived quantities plus seasoned commercial judgement: productivity rates, access allowances, phasing logic, and contingency that’s targeted where real uncertainty exists.

Measuring whether precision is improving

If you want to scale this approach, measure a few concrete metrics during pilots:

-

Hours per takeoff before vs. after model adoption.

-

Number of conditioning iterations per QTO.

-

Variance between the estimate and procurement quantities.

-

Frequency and value of scope-related change orders.

Seeing those numbers improve after one or two pilots is the best reason to expand the practice.

Start small, prove value, scale

You don’t need a full enterprise rollout to begin. Run a pilot on a representative floor or a repeatable trade. Share the one-page tagging guide. Run the pilot extract and compare it to a manual takeoff. Fix gaps, update the mapping table, and repeat. Small wins build confidence faster than sweeping mandates.

Conclusion

Cost precision is not a mystery; it’s a discipline. BIM Modeling Services create the structured, auditable inputs. Construction Estimating Services convert those inputs into priced, time-phased plans that stand up under scrutiny. Enforce a few simple rules — agreed LOD, consistent naming, pilot extracts, and dated rates — and you move from guessing toward certainty. The payoff is measurable: fewer surprises on site, cleaner procurement, and budgets that more closely match what actually gets built.